Wastewater is 99.9 percent water, but boy, that last little bit. Not that we need to dwell on it. To flush and forget is one of the great privileges of life in the developed world. Take the United States, where more than 80 percent of households connect to sewers. (Most of the rest have septic tanks.) A lift of a plug, a push of a lever, or simply the tug of gravity, and our wastewater is gone from our lives forever.

Unless you’re, say, Stanford assistant professor of chemical engineering William Tarpeh, whose research pursuits include harvesting ammonia for fertilizer from wastewater. Occasionally, at dinner parties, someone misinterprets his job and regales him with stories of gastrointestinal woe. He has to interrupt. “I’m not a poop doctor,” he says. “I am a person with a doctorate who studies poop and pee, and I don’t want to talk about your poop. That’s gross.” But writ large, he says, wastewater deserves our collective attention. It is replete with treasure, including nutrients, pharmaceuticals, minerals, and metal cumulatively worth billions of dollars. It is, he likes to say, a modern mine.

Tucked away on the east side of campus, the Codiga Resource Recovery Center offers a door to that mine. A demonstration site for a new way to treat sewage, the center is built on the idea that wastewater is not garbage to eradicate so much as ore awaiting refinement. Moreover, the center gives researchers rare access to “raw material” from a sewer running under Serra Street. “Anytime I tell my academic counterparts at other schools about Codiga, they’re literally jealous,” says Tarpeh, ’12. “I can take a golf cart there and have a tap that gives me sewer water, different types of sewer water, immediately. There’s something beautiful about it being on campus.”

His colleagues have also picked up their pails. “Wastewater is ore,” says Sebastien Tilmans, MS ’10, PhD ’14, Codiga’s former executive director and now a strategic adviser. “It’s five ores. It’s water, it’s energy, it’s materials, nutrients, and information. You have to remove the impurities, and then you have a valuable material.”

Here are four ways Stanford faculty are making the most of it. Hold your nose and jump in.

Water

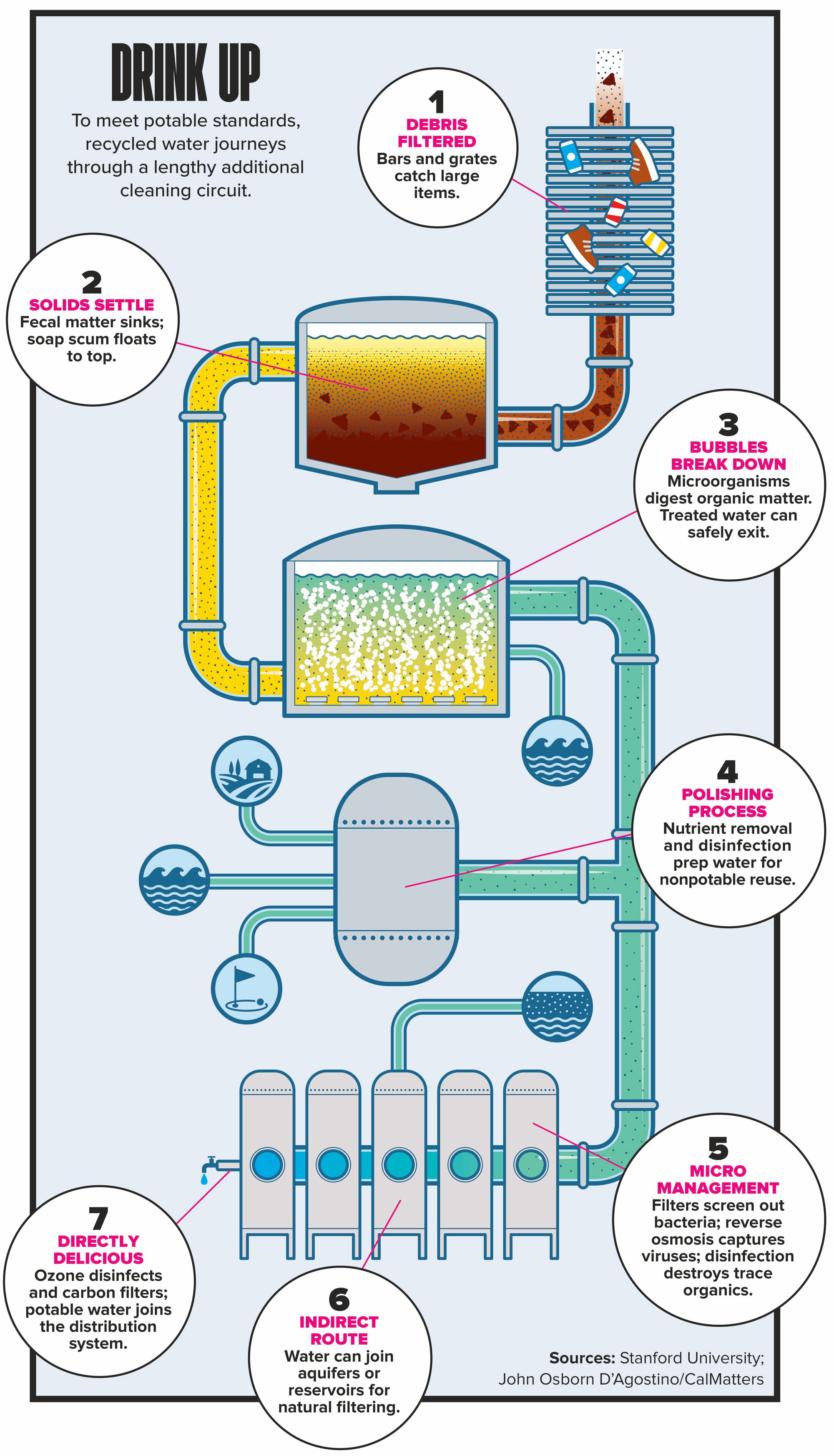

If you’re ever near Disneyland and want to visit a real Tomorrowland, the Orange County Water District is just 10 miles away. The utility runs the world’s largest water purification system for potable reuse. Each day, the district takes more than 150 million gallons of treated wastewater—which once would have flowed out into the Pacific—and puts it through three rounds of purification: microfiltration, which screens out bacteria larger than 1/300th the breadth of a human hair; reverse osmosis, which filters through pores a hundred times smaller than the average virus; and disinfection using ultraviolet light with hydrogen peroxide, which destroys trace organic compounds. The cleansed water is then mostly left to seep into Anaheim’s vast sandy groundwater aquifers, resurfacing months later at more than 200 wells that serve the area’s 2.5 million customers. You can try a sample on a tour of the facility. “It’s very pure,” says Megan Plumlee, MS ’04, PhD ’08, the district’s director of research. “I happily drink it.”

It’s just a taste of what’s on tap as the arid West looks to recycled wastewater to help quench a thirsty future. California’s Department of Water Resources estimates the state could lose up to 10 percent of its water supply by 2040 due to hotter and drier weather. “In the 21st century, we’ve come to a realization that we’re at the limits of what our water supply systems can provide,” says Richard Luthy, a professor of civil and environmental engineering. Purified wastewater, he says, makes an attractive backup. It’s local, it’s plentiful, it’s drought-resistant, and it’s economical relative to options like desalination. “We can’t conserve our way out of this.”

Richard Luthy

Richard Luthy

It’s tempting to think of drinking water and wastewater as opposite ends of the pipe, never the twain to touch. Drinking water treatment plants take in water from rivers, lakes, and below ground, bring it to potable standards, and send it to homes and businesses, where people drink, bathe, clean, and flush with it before sending it down the drain to sewage treatment plants for safe release into the environment. But these ends connect more than we might prefer to think. Texas provides a classic case of de facto water reuse. Dallas-Forth Worth discharges treated wastewater into the Trinity River, which, 200 miles later, provides Houston with its drinking water.

What’s newer are deliberately engineered ways to connect the ends. Orange County’s is an example of indirect potable reuse, where wastewater is cleansed to 99.9999999999 percent free of pathogens before it goes to an environmental buffer like a reservoir or an aquifer for further natural filtering and then to homes. Many areas lack the geography to accommodate this pit stop; not everywhere has Anaheim’s sandy aquifers. So, we come to the latest frontier in water reuse, enabled in California last year: direct potable reuse, via which utilities can skip the environmental buffer. After treating the water to even higher standards—demonstrating a 99.999999999999999999 percent removal rate of viruses and similarly high removal rates of protozoa—they may send the cleansed water directly into the water distribution system.

The San Francisco Public Utilities Commission, which provides Stanford with snowmelt from Yosemite’s Hetch Hetchy Valley (about as far from recycled wastewater as you get), is considering both indirect and direct reuse projects. The first would add purified wastewater to the general drinking supply in Crystal Springs Reservoir, visible from Interstate 280 in the northern Santa Cruz Mountains. The second would pipe it directly to the distribution system in San Francisco. “New water supplies ain’t growing on trees,” explains Steven Ritchie, ’76, MS ’77, the commission’s assistant general manager for water. “You’ve just got to find a way to live with what you’ve got. In the back of my mind, I’m always carrying around the notion of, What if we get into a biblical drought? There was a short period of time in 2014 where I was scared.”

Over the decades, the public has grown accustomed to reusing wastewater for irrigation on places like golf courses. (This requires a distribution system specifically for nonpotable recycled water, an expense that limits its benefit.) But people have found it harder to swallow the idea of recycled water coming out of their own taps. In a 2015 survey of 1,500 Californians by Stanford political science professor Bruce Cain and research colleague Iris Hui, only 11 percent of respondents said they were willing to drink recycled water.

The yuck factor appears to be only in our heads. In 2022, William Mitch, a Stanford professor of civil and environmental engineering, was the senior author on a paper in Nature Sustainability that compared groundwater, surface water, and recycled wastewater treated to potable standards. Given its intense treatment, Mitch had expected recycled water to be cleaner than drinking water derived from surface water—i.e., the rivers, lakes, and reservoirs that supply 70 percent of American tap water. Such bodies are often exposed to run-off, pesticides, and, as with Houston, the upstream discharge of other municipalities’ treated wastewater. And surface water treatment is typically not as thorough as the standards require for potable reuse. But Mitch was surprised to see how well recycled water compared with groundwater, which filters through protected basins. “Potable reuse water is in many cases comparable to groundwater, which is about the highest-quality water you typically have,” he says. “I’m convinced that it’s certainly safe from a pathogen point of view, and the toxicity is lower than conventional tap water.”

William Mitch

William Mitch

The dawning era of direct potable reuse does raise new questions, which Mitch is studying with Luthy and others. Ironically, one such question centers on whether the recycled water is essentially too clean. The treatment denudes the water of its microbiome, the untold number of microbes found on and in everything, says Kara Nelson, a professor of civil and environmental engineering at UC Berkeley who is working on the project. A typical glass of tap water, for example, might contain a million microorganisms. Recycled wastewater treated to potable standards has virtually none. While that’s not a problem by itself, it creates a void that will inevitably be filled by new bacteria, just as new plants will grow in a dug-over garden. The question is whether these newcomers will be friend or foe.

In the case of a system like Orange County’s, the microflora in the surrounding groundwater simply populates the purified wastewater, Nelson says. Something similar might occur in direct reuse when conventional water and recycled water mingle. It’s also possible the bacterial blank in the recycled water creates room for opportunistic pathogens. Nelson thinks that’s unlikely—the water is too low in nutrients—but it’s an important question to vet. The study will examine how differing ratios of conventional water and recycled water react when piped together. “This is a new practice,” she says. “We should be applying all of our best science to make sure that nothing unusual is going to happen.”

Ideally, results will help utilities integrate direct potable reuse with as little controversy as Orange County provides its recycled water. When people take the tour of the Orange County recycling facility, they end at the tasting sink, Plumlee says, where cups feature a motto inspired by the most common reaction. “Tastes like water . . . because it is water!”

Nutrients and Materials

To Tarpeh—a chemical engineer—the difference between a product and a pollutant so often comes down to its placement. Ammonia provides the perfect example. As the primary ingredient in commercial fertilizer, it’s what keeps half the planet fed. Each year, factories around the world spend billions of dollars on the high-pressure, high-heat reactions necessary to force nitrogen and hydrogen together to make it at scale.

Our bodies also produce significant amounts of ammonia as a byproduct of protein breakdown, which we purge as urea when we urinate. But when that ammonia ends up in our waterways—often via a wastewater plant’s discharge—it becomes a nuisance, or worse. It can overstimulate the growth of algae, depleting the water’s oxygen with deadly results. For a month in 2022, a red-tide algal bloom in the San Francisco Bay caused a massive fish kill, leading to new regulations requiring Bay Area treatment plants to vastly reduce their nitrogen discharge at substantial cost.

But what if we could harvest that ammonia—and other chemicals—from wastewater? It’s the core challenge in Tarpeh’s mission to reimagine wastewater not as waste at all, but as a “modern mine” full of constantly replenishing resources, from phosphorus to pharmaceuticals, waiting for the development of the right science to efficiently siphon them from the soup.

There are many ways to capture materials from wastewater. Mango Materials, a company co-founded by Allison Pieja, MS ’05, PhD ’11, and Molly Morse, MS ’04, PhD ’09, for example, converts methane created by the decomposition of solids in wastewater into biodegradable plastics. Tarpeh’s focus is on using chemistry and electricity to select nutrients from the liquid waste.

It’s a potentially lucrative endeavor. Tarpeh estimates that, around the world, municipal wastewater contains some $30 billion in chemicals annually, about a fifth of that ammonia. His main motivation, though, is to enable circular economies that reduce waste and ease environmental stresses. Industrial manufacturing of ammonia, for example, is responsible for some 2 percent of the planet’s carbon emissions, and it worsens nitrogen pollution. Tarpeh also wants to help the developing world. Farmers in sub-Saharan Africa pay dearly for fertilizer from faraway factories, but anywhere there are people, there’s pee.

To that end, Tarpeh has developed a method of “electrochemical stripping” that uses electrical charges to pull ammonia out of urine and other wastewaters, resulting in an ammonium sulfate solution usable as fertilizer. It’s the centerpiece technology of a company called Recovered Potential that’s spinning off from his lab.

William Tarpeh

William Tarpeh

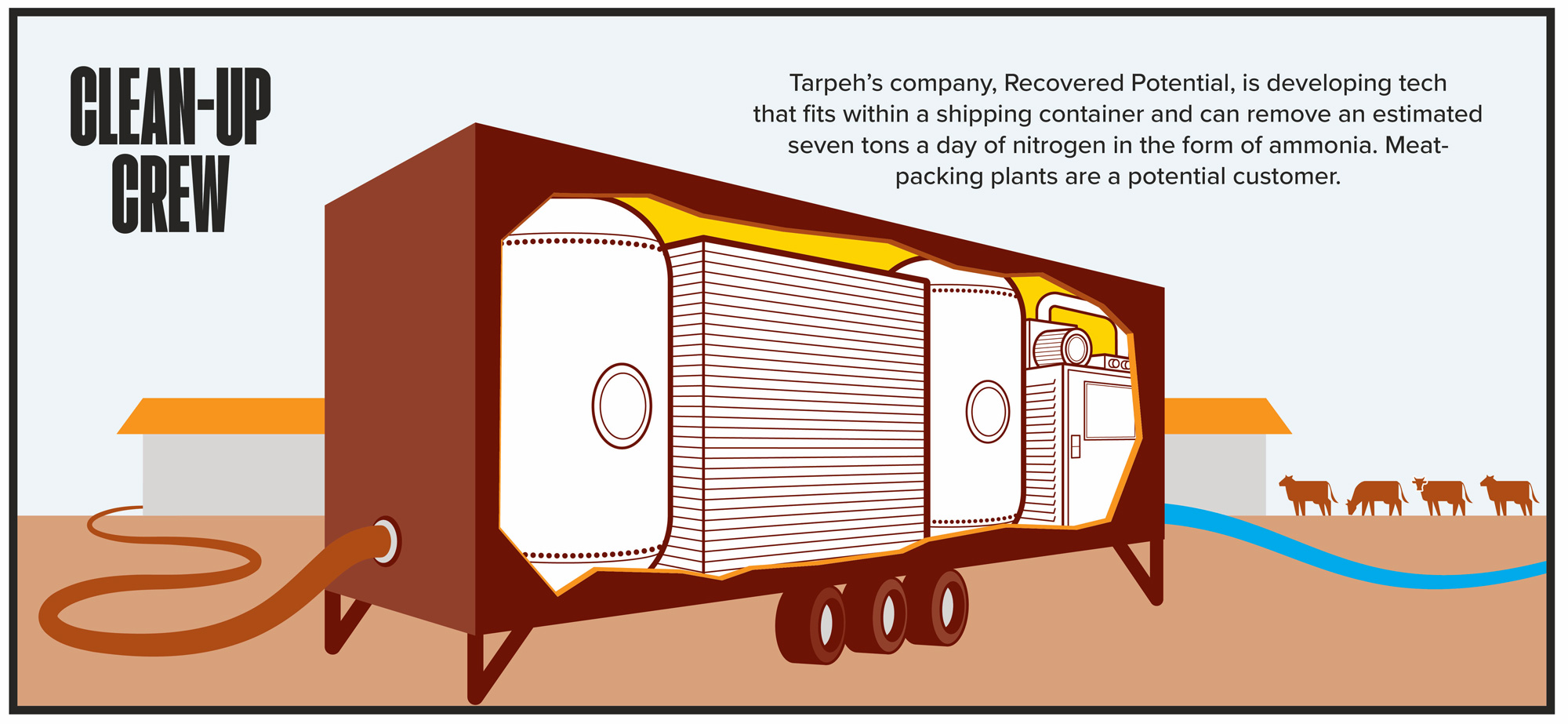

Recovered Potential is developing tech that fits within a shipping container that can be brought on site to remove an estimated seven tons a day of nitrogen in the form of ammonia—an alternative to building a treatment system from the ground up, says co-founder Kindle Williams, a postdoc in Tarpeh’s lab. “Being able to ship that in, rather than deal with siting, excavation, pouring lots of concrete—it’s like a couple of weeks versus three years of work,” she says. “We’ve found a lot of folks who were pretty compelled by that vision.”

Potential customers include meat-packing plants, which have high levels of ammonia in their wastewater due to protein degradation in blood and renderings, Williams says, and who anticipate new EPA regulations will require them to remove far more nitrogen than they presently do. Recovered Potential would then offer the removed ammonia as a low-cost fertilizer to city groundskeepers or local farmers.

Tarpeh sees further. Nitrogen was just a start, in part because of its abundance. But there are many more chemicals in wastewaters to focus on: potassium, phosphorous, lithium. Think of a pollutant, he likes to say. Can you turn it into a product again? Why not try?

Energy

Poop, the saying goes, rolls downhill, which explains why wastewater plants are almost always found on the lowest-lying land available. Better to let gravity do the work than to pay for pumping.

But the free ride soon ends with a squelch at the treatment plant. Sewage treatment is one of the most energy-intensive sectors in the United States. “Oftentimes it’s one of the single biggest energy users on a municipality’s energy budget,” says Tilmans, the Codiga strategic adviser. Stanford researchers want to flip that picture on its head. “Traditionally, a wastewater treatment plant is this thing that uses lots of energy,” Tilmans says. “We’re saying, ‘What if it was a power plant?’ ”

Sebastien Tilmans

Sebastien Tilmans

The proposed solution, like the problem, has much to do with bacteria.

When sewage arrives at a typical treatment plant, larger solids—yes, lots of that—are left to settle while soaps, oils, and other surface scum are skimmed off. The remaining water is sent into aeration tanks where it is set upon by “activated sludge,” a time-tested technique that uses aerobic bacteria to feast on the dissolved organic material still clouding the water, essentially eating it clean. But to keep these oxygen-loving bacteria thriving, treatment plants use bubblers, blowers, and other devices—energy hogs all—to force air into the water as if they’re aerating giant aquariums.

The settled solids, meanwhile, head to a different bacterial fate. They are sent to airtight digesting tanks to be consumed by anaerobic microbes, which thrive in the absence of oxygen and convert the waste into biogas, mostly methane, a fuel similar to natural gas that can generate electricity on site or be delivered to the gas grid.

Which raises a question. Since these anaerobic bacteria produce energy, don’t need costly oxygen blowers, and are part of a process that uses less electricity, why not simply use them to consume both the solid and the dissolved waste? Alas, anaerobic bacteria make for dawdling decomposers. Their slow growth makes them tenfold less efficient at digesting organics than their aerobic kin, says Mitch, the civil and environmental engineering professor. That slower pace is fine for consuming the concentrated solids that are removed from the wastewater. But anaerobic bacteria are far too slow to take on the organics dissolved through the millions of gallons of remaining water. “Historically, we’ve used aerobic bacteria because you can get the job done in a reasonable time, and your treatment plant doesn’t need to take up the entire city,” Mitch says.

The water and wastewater sector account for 3%-5% of annual electricity consumed in the United States.

For more than a decade, Stanford researchers have been working on getting around this conundrum via technology pioneered by the late Stanford civil engineering professor Perry McCarty. The researchers grow anaerobic bacteria on grains of activated carbon—the stuff you see if you crack open a Brita filter. The grains operate like a vast flotilla of tiny bacterial bases, which collectively provide the surface area for the microbes to grow far beyond what would normally occur. As the wastewater circulates within enclosed tanks, the bacteria are present in such numbers that their plodding pace is offset by their increased population. “If you grow a dense enough anaerobic biofilm on these activated particles, you make up for the inefficiency of anaerobic bacteria, because you essentially have 10 times the biomass,” Mitch says.

After a promising test at Codiga, Stanford researchers opened a multimillion-dollar pilot operation, largely funded by the California Energy Commission, within Silicon Valley Clean Water in Redwood City. Since 2021, the pilot has been using anaerobic bacteria to treat 24,000 gallons of sewage a day. According to a report released last year, the anaerobic pilot treated wastewater in less time, with an 82 percent smaller carbon footprint, than a conventional aerobic system. And it not only used less electricity but also created methane to generate much more power than it used. If a plant the size of Silicon Valley Clean Water adopted the technology, estimates indicate it could go from consuming the same power as about 770 average American households to exporting enough power to supply about 630 homes. It’s the world’s most energy-positive treatment plant, Tilmans says.

Estimates indicate the plant could go from consuming the same power as about 770 average American households to exporting enough power to supply about 630 homes.

The process is not perfect. The anaerobic treatment, for example, did not remove nitrogen. It was also a tiny demonstration relative to municipal needs. Silicon Valley Clean Water treats an average of 13.5 million gallons of wastewater a day, more than 500 times the pilot’s capacity. In a world involving public health regulations, public money, and extremely expensive infrastructure investments, Stanford’s results were more an intriguing proof of concept than an invitation to follow suit.

“Wastewater sectors are typically conservative in their decision-making when adopting new technologies,” says Chungheon Shin, Codiga’s research director. They need to meet regulatory standards and also stay within a confined budget. He says researchers are partnering with private industry and federal agencies to create larger demonstrations—say, 1 million gallons per day—to strengthen proof of concept.

The system’s long-term appeal may only increase with the rising interest in recycling wastewater, Tilmans says. Cleaning wastewater to drinking standards is, he says, an energy suck that will only worsen the already considerable electrical demands of wastewater treatment. It’s much easier to absorb that jump if you’re also a power plant.

Information

In June, amid concerns about a national surge in measles, Yolo County in California’s Central Valley confirmed just its third case in the past decade. It was worrying news but not surprising. A week before the patient walked into the ER, officials had issued a call for vigilance. Wastewater surveillance had already detected the disease nearby.

Five years ago, the idea that sewage would inform public health was barely a pipe dream. Wastewater-based epidemiology—using sewage to track community pathogens—had been used in a limited way for decades, mostly to monitor global polio outbreaks. But even many health experts knew nothing about it. “I don’t think I’d heard about it,” says Sara Cody, ’85, who retired this year after more than a decade as Santa Clara County’s health officer. “It was not on my radar.”

That would change quickly during the pandemic, largely thanks to research led by Alexandria Boehm, a Stanford civil and environmental engineering professor. Boehm is the principal investigator of WastewaterSCAN, which tracks more than a dozen infectious diseases at nearly 150 treatment plants across the country, including the Sacramento Regional Wastewater Treatment Plant that detected measles the week before the Yolo County case was confirmed.

Alexandria Boehm

Alexandria Boehm

Before 2020, Boehm wasn’t much more versed in wastewater-based epidemiology than Cody. She was more attuned to sewage’s risks to public health after, say, a spill, than to its potential benefits as a community diagnostic. But as reports of a troubling new disease kept coming out of China, she and Krista Wigginton, a University of Michigan professor of environmental engineering at Stanford on sabbatical, applied for a rapid-response grant from the National Science Foundation to look for signs of the virus in wastewater. They were initially turned down on grounds that the research wasn’t domestically relevant. That soon changed.

By March 2020, Boehm and a group of students and postdocs were sending email requests for wastewater samples around the country, the replies stacking up outside the front door of Boehm’s home. (Campus was closed to FedEx.) As they waited for deliveries, the group was also able to sample from the Codiga Resource Recovery Center, which taps Stanford’s sewer, giving them a steady supply of material to test their methods, Boehm says.

The prevailing belief was that enteric diseases—i.e., those affecting the gut—would show up in wastewater; respiratory illnesses, like COVID, would not. That proved incorrect, but a larger question loomed about the project’s viability. Sewers are not methodical collection systems. People shed viruses in differing amounts. Thousands of small pipes flow into one big pipe. Some “deposits” travel miles, others come from right next door. Those varying journeys result in exposure to different temperatures. How could anyone draw reliable, actionable information from such a soup? Boehm expected big variances in the readings.

But as the researchers honed their methods, they found that pea-sized samples of solids—accumulated in tiny samples of untreated influent at treatment plants over 24 hours—consistently mirrored data from clinical testing, even in sewer systems that serviced hundreds of thousands of people. As clinical cases rose or fell, the levels in the sewage responded in lockstep. The researchers weren’t finding the actual virus, which doesn’t survive long outside the body, but telltale fragments of nucleic acids. “This really shouldn’t work as well as it does, right? Because there are so many factors along the way,” says WastewaterSCAN co-principal investigator Marlene Wolfe, ’11, an assistant professor of environmental health at Emory University who was a Stanford postdoc when the project started. “But we find it gives us this really clear picture of what’s going on in a community over time, from our smallest sites that serve just over 10,000 people, up to 4 million, with the same techniques.”

‘We would have been flying blind had it not been for wastewater.’

The system went public in November 2020 with results from eight wastewater treatment plants in the Bay Area and Sacramento. Cody was an early believer. “You can see the case data and the wastewater data—and they’re exactly the same.” It proved crucial after the rise of home testing dramatically reduced publicly reported clinical testing. “We would have been flying blind had it not been for wastewater.” On December 16, 2021, ahead of the holiday travel season, Cody gave a forceful public warning about an impending “deluge” of the Omicron variant. At that point, there had been just 10 confirmed Omicron cases in Santa Clara County. But tests showing its presence in all four of the county’s wastewater plants convinced her of the brewing storm. An explosion of new COVID cases followed in the county, reaching a peak for reported cases during the entire pandemic in mid-January. “I felt very confident sounding the alarm,” Cody says.

It was, says Boehm, a huge moment in public awareness of wastewater’s powers.

As concerns about COVID have ebbed, WastewaterSCAN has developed tests for more diseases, including mpox after the global outbreak reached California in 2022. Cody again used wastewater data to guide Santa Clara County’s response. Disease-causing bacteria—with larger, more complex genomes—have been harder to track, but WastewaterSCAN has had a run of success identifying viral diseases, from RSV to norovirus to measles. The researchers post the data for their sites—spanning from Hawaii to Maine—online. “I don’t think I could have possibly imagined where we’d be at now at this point,” Wolfe says.

‘Wastewater represents this community biological sample that has all sorts of information in it about the health and well-being of a community.’

Their success is rooted in many factors—from philanthropic support to the incredible sensitivity of genetic-detection tools. It is also a reflection of the wealth of information within wastewater, a vastness Wolfe and Boehm have both come to better grasp over time. A virus may or may not shed in a person’s feces, but that same person is also likely flushing skin cells into the system when they bathe, saliva when they brush their teeth, blood cells when they rinse a wound, and more. It adds up to treasure in the trash, a window on our collective health now and perhaps in the future. Boehm and Wolfe have also used wastewater data to map out areas in the country with the most antibiotic resistance.

Wastewater is not something we as humans want to be around or even to think about, Boehm says. But it’s important. “We don’t like it. We don’t want it close to us,” Boehm says. “But wastewater represents this community biological sample that has all sorts of information in it about the health and well-being of a community. Who knows where this technology will take us?”

There’s an AI for ThatWastewater plants have always run up big power bills, but they’re getting even steeper, especially in California, says Meagan Mauter, an associate professor of photon science at the SLAC National Accelerator Laboratory and the research director of the National Alliance for Water Innovation. Not only has the price of electricity in the state soared in recent years, but many treatment plants—including those in the Bay Area—need more of it, due to factors that include new environmental requirements. “We’re seeing the power demands for wastewater treatment plants skyrocket,” she says.

While Stanford colleagues are looking at overhauling the treatment process to make it energy positive, Mauter’s lab is studying a more immediate solution: using artificial intelligence to better manage energy use in the existing system. Working with the Silicon Valley Clean Water treatment plant in Redwood City—a recurrent collaborator with Stanford researchers—Mauter’s lab has run a virtual pilot that seeks to find the ideal times to consume outside energy versus creating and storing its own, a potentially big deal when there’s a fourfold difference between peak and off-peak market rates. Silicon Valley Clean Water runs generators on the biogas created by decomposing solid waste, including infusions of fats, oils, and grease from food waste. It makes sense to burn those energy-rich items when electricity from the grid is at its most expensive, Mauter says, just as it makes sense to charge the plant’s battery packs and, when possible, run operations like aerators at cheaper times. Sounds simple, but on a second-by-second basis across multiple operations, with variables like temperature affecting outcomes, it’s not, she says. “The consumption and the generation of power is so dynamic throughout the day that it is absolutely impossible to heuristically control these complex interacting processes,” she says. “You need a machine to do it.” Results from the virtual pilot suggested the AI could have saved the treatment plant 23 percent on electricity during the winter and even more in the summer, when differences between peak and off-peak rates are greater, she says. The bigger test in the year to come: Mauter’s AI will start directing energy management at the plant. |

Sam Scott is a senior writer at Stanford. Email him at sscott3@stanford.edu.

Headshots, from top: Courtesy Richard Luthy; Nancy Rothstein; Rod Searcey; Courtesy Sebastien Tilmans; Saul Bromberger and Sandra Hoover Photography; and Nancy Rothstein